GPa Grade Macroscopic Assembly of Graphene Film Stronger than Steel Plate

Time: 2020-05-28 visit times :53

Macroscopic graphene assemblies such as fibers, films, aerogels, and nonwoven fabrics bridge the gap from nanometer to macroscopic, which is conducive to the practical application of graphene. Despite great progress in the research of high-strength graphene fibers, continuous fabrication of high-strength graphene films remains a challenge. As a two-dimensional planar macromolecule, single-layer graphene has excellent mechanical, electrical and thermal conductivity properties in the in-plane direction. At the same time, it is very flexible in the outward direction. This inherent flexibility makes graphene prone to random folds during the macroscopic assembly process, which will affect the structure and properties of the macroscopic assembly. In particular, during the liquid phase processing of GO liquid crystals, both the local orientation of the liquid crystals and the shrinkage during the drying process can lead to random folds on the surface of the graphene macroassembly.

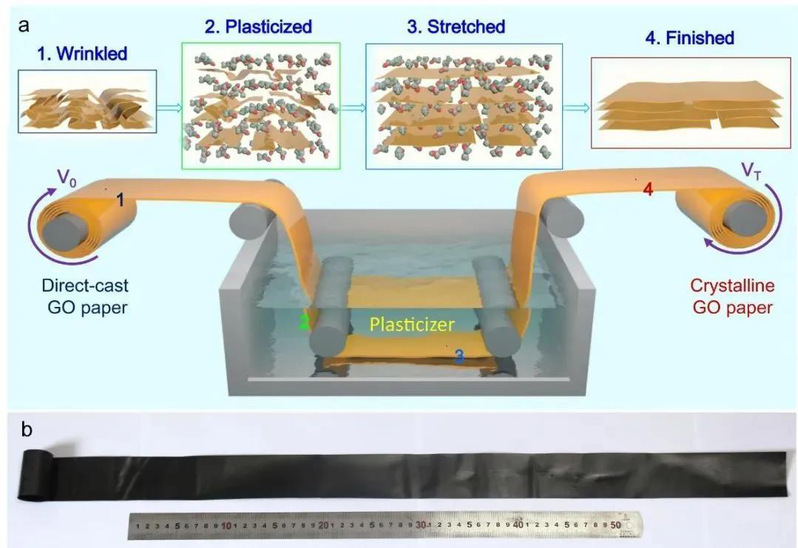

Fig. 1 The preparation process of the crystallized GO film. B Digital photograph of a meter-grade graphene membrane

To this end, the team of Chao Gao and Xu Zhen from Zhejiang University, in collaboration with the team of Yilun Liu from Xi 'an Jiaotong University, realized the continuous high-strength graphene assembly membrane by superplastic stretching. Continuous Graphene Papers with Gigapascal Strength byIntercalation Modulated Plasticization was published in Nature Communications (2020,11,2645 DOI:10.1038/s41467-020-16494-0).

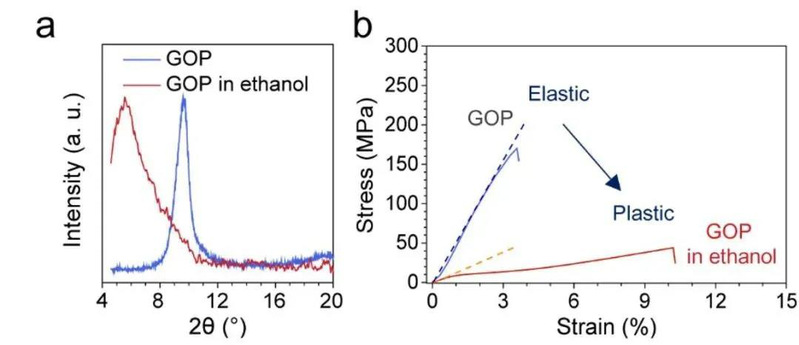

Fig.2 Brittle-plastic transition of GO films. a.XRD of GO films before and after plasticization b.Typical mechanical curves of GO films before and after plasticizing.

The researchers found that plasticization was modulated between the GO membranes, enabling the superplastic stretching of the GO membranes. Through the intercalation with ethanol solvent, the interlayer spacing of GO films increased from 0.9 nm to 1.58 nm, which reduced the interaction between the layers, thus giving the GO films obvious plastic deformation and increasing the ultimate elongation at break by 230%. The researchers used this plasticizing to fully flatten the wrinkled structures inside the GO films, and then dried and reduced them in the stretching state to continuously produce highly ordered graphene films.

Zhe Da Road 38, Hangzhou 310027, China

Tel : 86-571-87951308

Fax : 86-571-87951592

Email : ciciliu33@zju.edu.cn